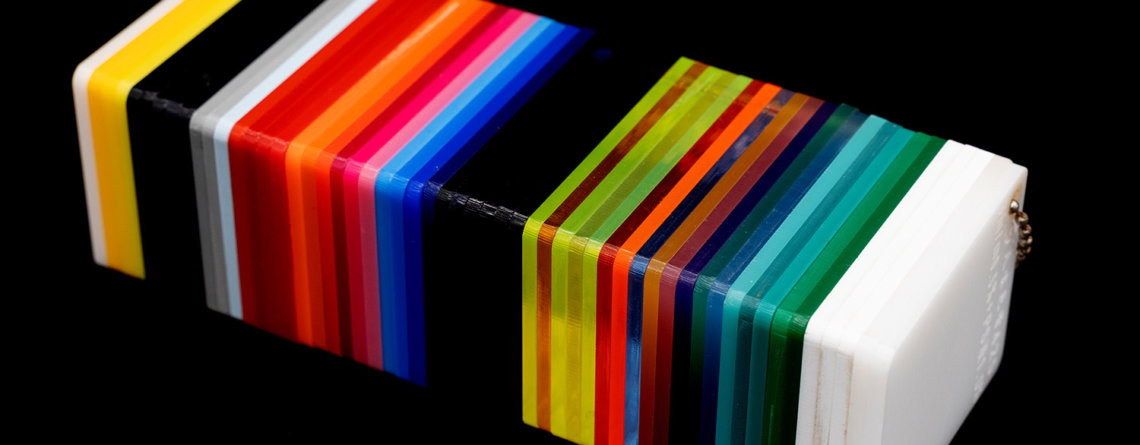

تتأثر تكلفة منتجات الأكريليك أيضًا بجودة اللوح. تميل الواح الأكريليك عالية الجودة ، المصنوعة من مواد خام نقية وخضعت لتدابير صارمة لمراقبة الجودة ، إلى أن تكون أكثر تكلفة من ألواح الأكريليك المعاد تدويرها منخفضة الجودة. ومع ذلك ، فإن الواح الأكريليك عالية الجودة توفر وضوحًا أفضل ، واتساق الألوان ، والمتانة ، مما قد يؤدي إلى عمر أطول وعائد أفضل على الاستثمار بمرور الوقت.

يمكن أن يؤثر حجم منتج الأكريليك أيضًا على التكلفة. قد تتطلب الواح أو منتجات الأكريليك الأكبر حجمًا مزيدًا من المواد الخام وخطوات معالجة إضافية ، مما قد يؤدي إلى زيادة التكلفة. بالإضافة إلى ذلك ، قد تتطلب المنتجات الأكبر حجمًا معدات أو أدوات متخصصة للتشكيل والتركيب ، مما قد يزيد التكلفة الإجمالية.

يؤثر تعقيد التصميم أيضًا على تكلفة منتجات الأكريليك. قد تتطلب التصميمات المخصصة أو الأشكال المعقدة مزيدًا من الوقت والخبرة لإنتاجها ، مما قد يزيد من تكاليف العمالة المرتبطة بعملية الإنتاج. قد تتطلب التصميمات المعقدة أيضًا المزيد من المواد الخام أو خطوات المعالجة ، والتي يمكن أن تضيف إلى التكلفة الإجمالية.

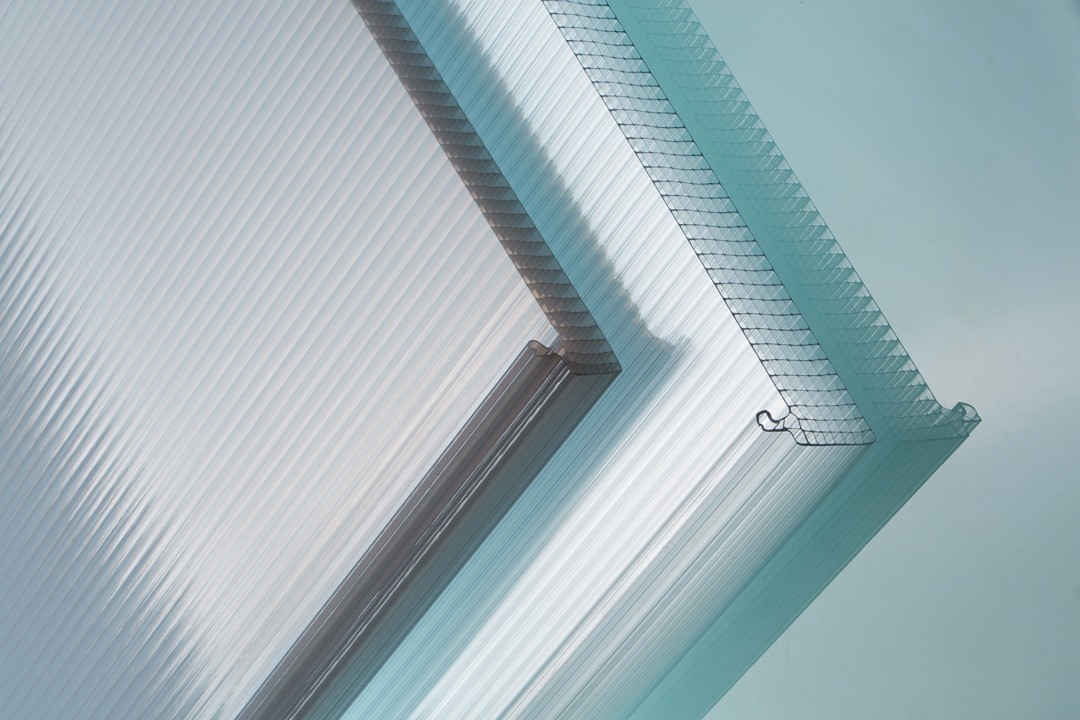

يمكن أن يؤثر تطبيق منتج الأكريليك أيضًا على التكلفة. على سبيل المثال ، قد تتطلب منتجات الأكريليك التي سيتم استخدامها في البيئات الخارجية معالجات أو طلاءات إضافية لحمايتها من الأشعة فوق البنفسجية والعوامل الجوية ، مما قد يؤدي إلى زيادة التكلفة. وبالمثل ، قد تتطلب منتجات الأكريليك التي سيتم استخدامها في المناطق ذات الازدحام الشديد مادة أكثر سمكًا أو مقاومة للتأثيرات ، والتي يمكن أن تزيد أيضًا من التكلفة. أخيرًا ، تجدر الإشارة إلى أن تكلفة منتجات الأكريليك يمكن أن تتأثر بالطلب والعرض في السوق.

يمكن أن تؤثر التغييرات في توافر المواد الخام والتقلبات في تكاليف الإنتاج والتغيرات في طلب السوق على تكلفة منتجات الأكريليك بمرور الوقت. في الختام ، يمكن أن تختلف تكلفة منتجات الأكريليك اعتمادًا على مجموعة متنوعة من العوامل ، بما في ذلك جودة المواد وحجم المنتج وتعقيد التصميم والتطبيق وطلب السوق. ومع ذلك ، في كثير من الحالات ، يمكن أن تكون منتجات الأكريليك خيارًا أكثر فعالية من حيث التكلفة من المواد الأخرى نظرًا لسهولة إنتاجها ، وخفة وزنها ، ومقاومتها للصدمات.