Polycarbonate sheets

Polycarbonate sheets are a type of durable, transparent plastic used in a wide range of applications due to their excellent impact resistance, lightweight properties, and optical clarity.

Key Features:

High Impact Resistance: 250x stronger than glass, often used as a safer alternative.

Lightweight: Easier to handle and install than glass.

UV Protection: Available with UV coating to resist yellowing and degradation.

Weather Resistance: Suitable for both indoor and outdoor applications.

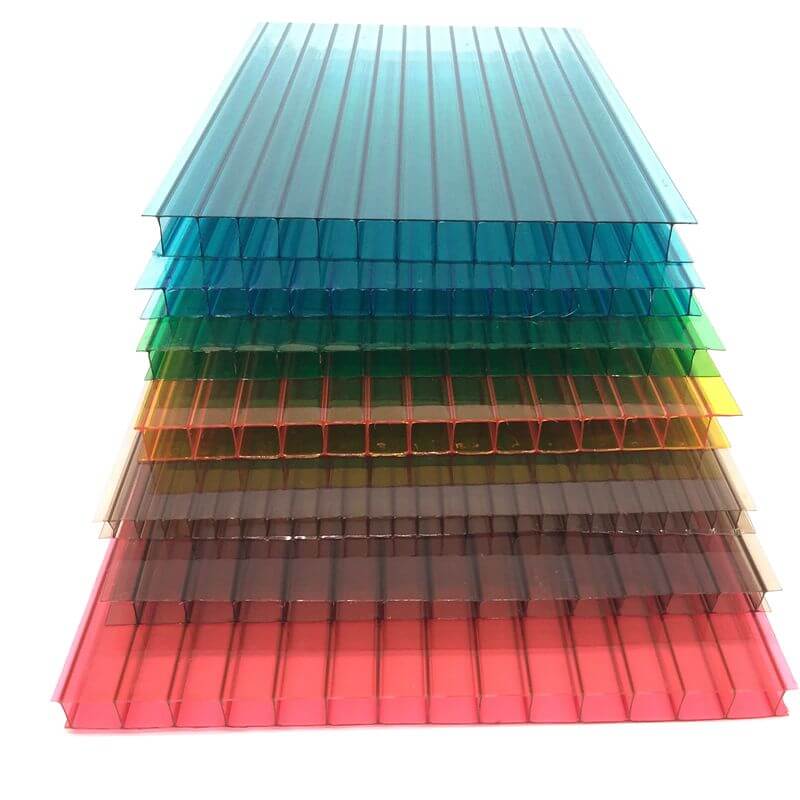

Thermal Insulation: Especially in multiwall polycarbonate sheets.

Flame Retardant: Often meets fire safety standards.

Common Types:

Solid Polycarbonate Sheets

Clear like glass, used for windows, safety glazing, machine guards.

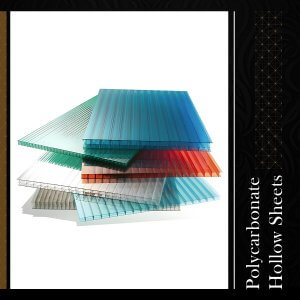

Multiwall Polycarbonate Sheets

Hollow structure for better insulation; ideal for roofing, greenhouses.

Corrugated Polycarbonate Sheets

Wavy profile, commonly used for roofing and siding.

Textured or Embossed Sheets

Frosted or patterned surface for privacy or decorative applications.

Typical Applications:

Skylights and roofing panels

Greenhouses and nurseries

Safety glazing and machine guards

Signage and light diffusers

Carports and bus shelters

Interior design and partitions

Get in touch

- Factory Address: The first industrial zone, El Herafeyeen A, plot 64, Badr City

- Showroom Location : Mirage Mall , First Floor

- Phone: 01067011170

- Phone: 02 25725274

- Mail: [email protected]

Contact Us

Error: Contact form not found.

Easy to Install

easily cut, engraved, written on, bent, and installed .

UV coated

Treated to resist sun, heat, and weather conditions.

100% Strong & Durable

Offers excellent transparency and brightness

Privacy

Does not absorb water or get damaged easily