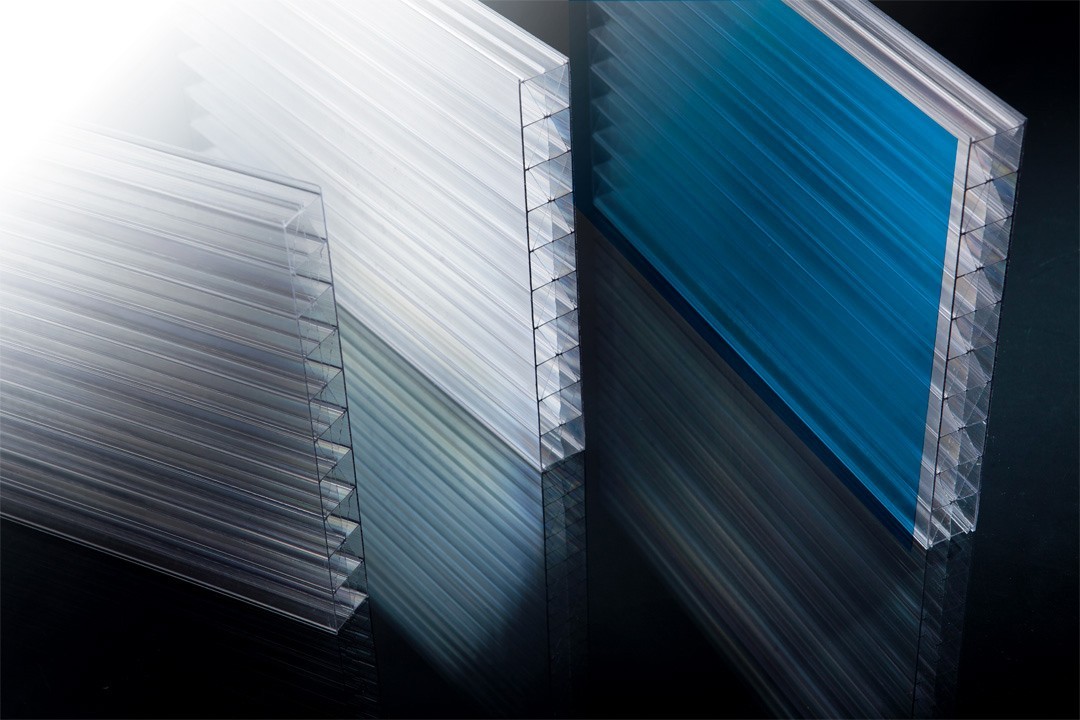

Polycarbonate sheets

Polycarbonate sheets are one of the man-made materials polycarbonates. Its exceptional properties and properties make it possible to easily apply polycarbonate products in various construction areas.

Polycarbonate is lightweight, durable, and highly resistant to the effects of heat.

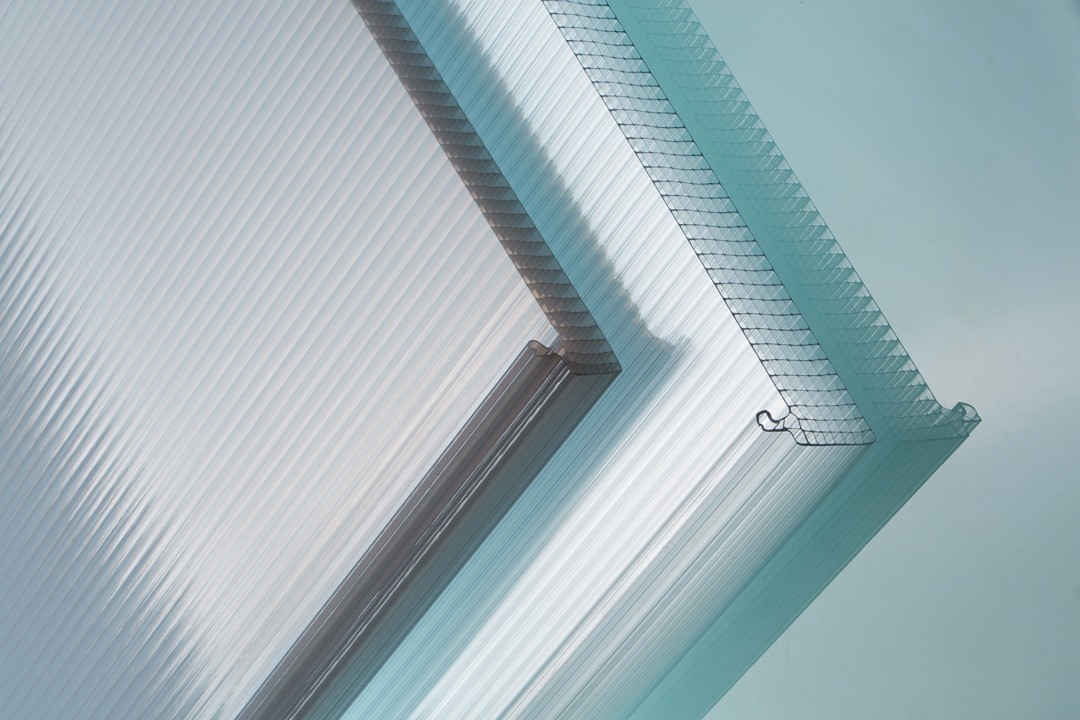

Fiber Polycarbonate sheets

Polycarbonate as an organism is a solid, colorless polymer used in the production of granules.

It is durable, lightweight, optically transparent, and plastic, frost-resistant, is a good insulator, and very durable.

From a chemical point of view, polycarbonates are synthetic polymers.

These are the propagation products of diphenyl phenol with carbonic acid derivatives.

The most common polycarbonate obtained from diphenyl propane and phosgene.

The special properties of polycarbonate are due to the unique structure of its molecules.

It is analogous to a long chain with repeated bonds, linked together by carbonate groups (-O- (C = O) -O-).

It is due to the length of their molecules that polymers differ from other materials by plasticity, light, and durability.

These molecules are called macromolecules, and the compounds that make them are polymers.

Polycarbonate is a thermoplastic (thermoplastic) polymer.

This means that it restores its properties upon hardening, regardless of how many times it dissolves.

At a high temperature (250 ° C), the physical bonds between the decay of its molecules, and the physical properties of the polycarbonate, such as hardness and strength, disappear and go into solubility.

The particles themselves maintain the complement, and when the smelting melts and solidifies, the physical bonds between them are established again, and the polycarbonate becomes the same as it was before the smelting process.

Due to this polycarbonate can undergo multiple processing, which makes the material particularly attractive from an environmental point of view.

What are the Advantages of polycarbonate?

Resistant to mechanical stress.

Lightweight material, easy to install, and cold-formed.

Noise absorption properties, light speed of up to 80%, high degrees of transparency, and light propagation.

Thermal insulation properties It has already been mentioned that the temperature conditions of the use of polycarbonate have a high resistance to various influences, and various weather phenomena, now it should be noted that different degrees of polycarbonate can be used under different temperature conditions thanks to its device, i.e. the voids in the filled bridges With air.

Polycarbonate is an environmentally friendly material, as it is non-toxic in its components.

Flame retardant, meaning that polycarbonate, chemicals such as plastics, and various fabrics are added to it in manufacturing, and it is in order to inhibit, prevent or delay the formation of ignition and flame at the time of a fire. Fire resistance at very high temperatures, materials melt, but do not allow the flame to spread, Does not release toxic substances.

Cold bending flexibility and cellular polycarbonate elasticity allow them to be applied in almost any geometric shape design.

Double and triple-layer polycarbonate sheets are manufactured in various colors and degrees of transparency.

Watch also

Properties of polycarbonate :

- Polycarbonate is a lightweight, durable plastic that is highly resistant to the effects of heat.

- Polycarbonate is designed for use in the most traditional roofing and glazing applications

This material is not only resistant to corrosion and refinement, but also withstands sharp temperature fluctuations without changing its properties.

Thanks to the application of an additional protective layer of UV rays, polycarbonate acquires resistance to ultraviolet rays.

Cutting, joining, cold bending, and drilling are among the processing options that can be applied to polycarbonate.

Areas of use: Hollow polycarbonate fibers are used in the installation and construction of structures and roofs. Many people today use these materials for construction: arch constructions, canopies for cars.

Blinds over entrance doors to dwellings are soundproofed materials that lie between railroad tracks and high-speed highways. Public transport parking awnings. It is used in greenhouses.

Polycarbonate installation method

Fiber Polycarbonate sheets

Fiber Polycarbonate

You can only fold the sheets toward the linear disk. Otherwise, the fibers will simply form. Make sure to close open channels around the edges of the panels. Otherwise, water and dust will be collected.

When installing screws, dowels it is recommended to first drill a hole in the sheet 1 mm larger than the diameter of the screw.

Excellent for building public transit stations, glazing of footpaths, all kinds of buildings and roof structures, and building arch structures.

Cell polycarbonate is an indispensable material in the construction of sports facilities. Sports complexes, as a rule, require more lighting, so they try to apply light-penetrating materials to their roof, which is why they are suitable. It has proven itself as the best material for building hockey boxes, courts, and all kinds of booths for training and commentators. Polycarbonate is also convenient to solve the interior of sports facilities, it is simple, beautiful, and does not require effort in cleaning.

The main use of cellular polycarbonate is its use in building greenhouses and greenhouses. Plantations are not the best materials used to roof and decorate shepherds and crop growers.

Polycarbonate prices :

The polycarbonate element can have different sizes of the panels accordingly, the price depends on the size of the panels this material. Therefore, today the cell polycarbonate can be of two types.